Office: Tian 'an Digital City, Wujin District, Changzhou City, Jiangsu Province

Factory: No. 49, Limao Road, Lijia Town, Changzhou City, Jiangsu Province

[email protected]

Max pressure:9KN

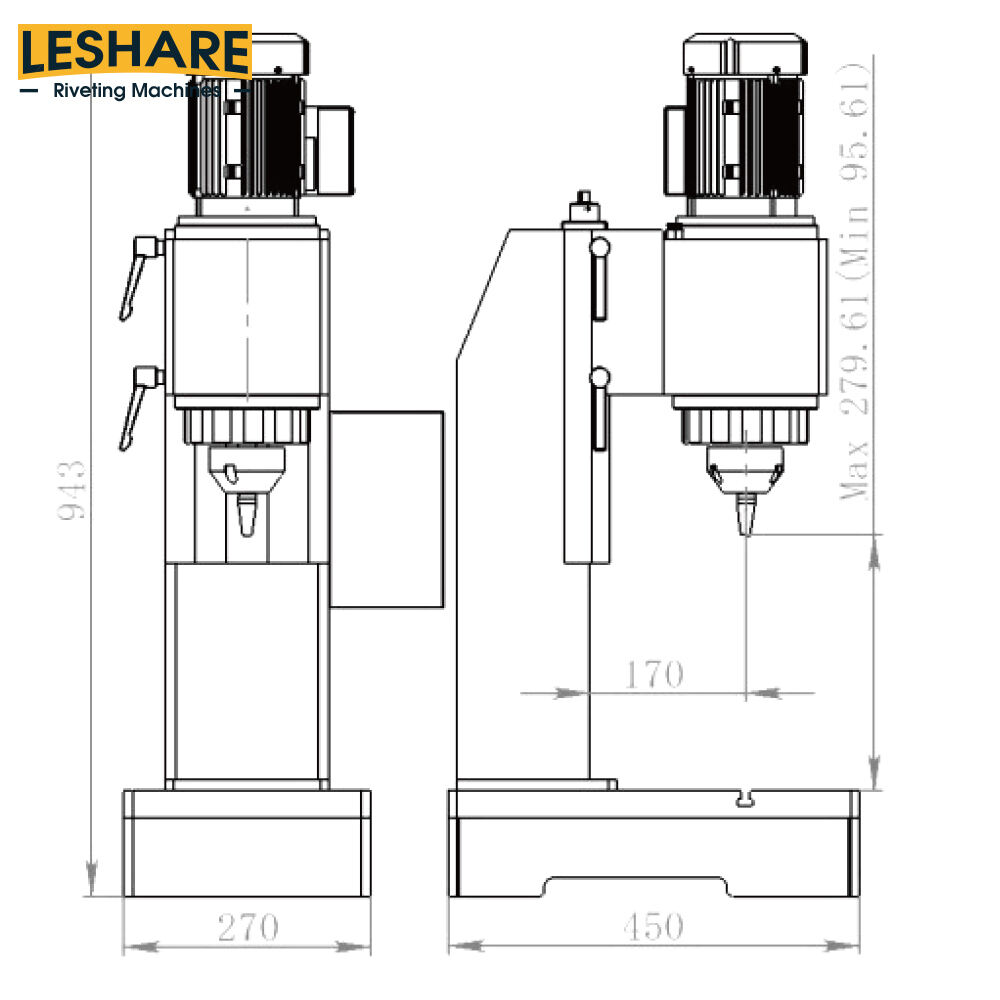

Depth throat:170mm

Rivet range:0.5mm-6mm

Type:Pneumatic

9KN Pneumatic Radial riveting machines

The pneumatic Radial riveting machines is suitable for connecting steel plates, stainless steel plates, aluminum plates and non-metallic liners. The typical components connected by the hydraulic riveting machine include: roof windows, bumpers, exhaust pipes, fuel tanks, brake housing covers, doors, instrument frames, engine brackets, engine hood covers, rear cover plates, coolers, seats, window regulators, mufflers, refrigerator doors, washing machine housings, fan housings, copier bases, computer shells, dental machine enclosures, and so on.

Technical features of the pneumatic rotary riveting machine - Model 141

Unique crushing and grinding working principle

During the riveting process of the rotary riveting machine, the rivet head makes contact with the workpiece (rivet) at an angle of 3° or 5°. This riveting method is different from the traditional press riveting machines, blow riveting machines or stamping riveting machines. The rotary riveting machine's swinging riveting enables the rivet to undergo local deformation gradually extending to the entire body, eliminating internal stress, preventing the rivet from becoming thickened, bent or deformed, effectively improving the smoothness of the riveted surface, and thus achieving the ideal riveting effect.

2. The rivets are suitable for a wide range of applications.

Suitable for various materials including stainless steel, medium and low carbon steel, copper and iron, and aluminum, for both solid, hollow and hollow-core rivets.

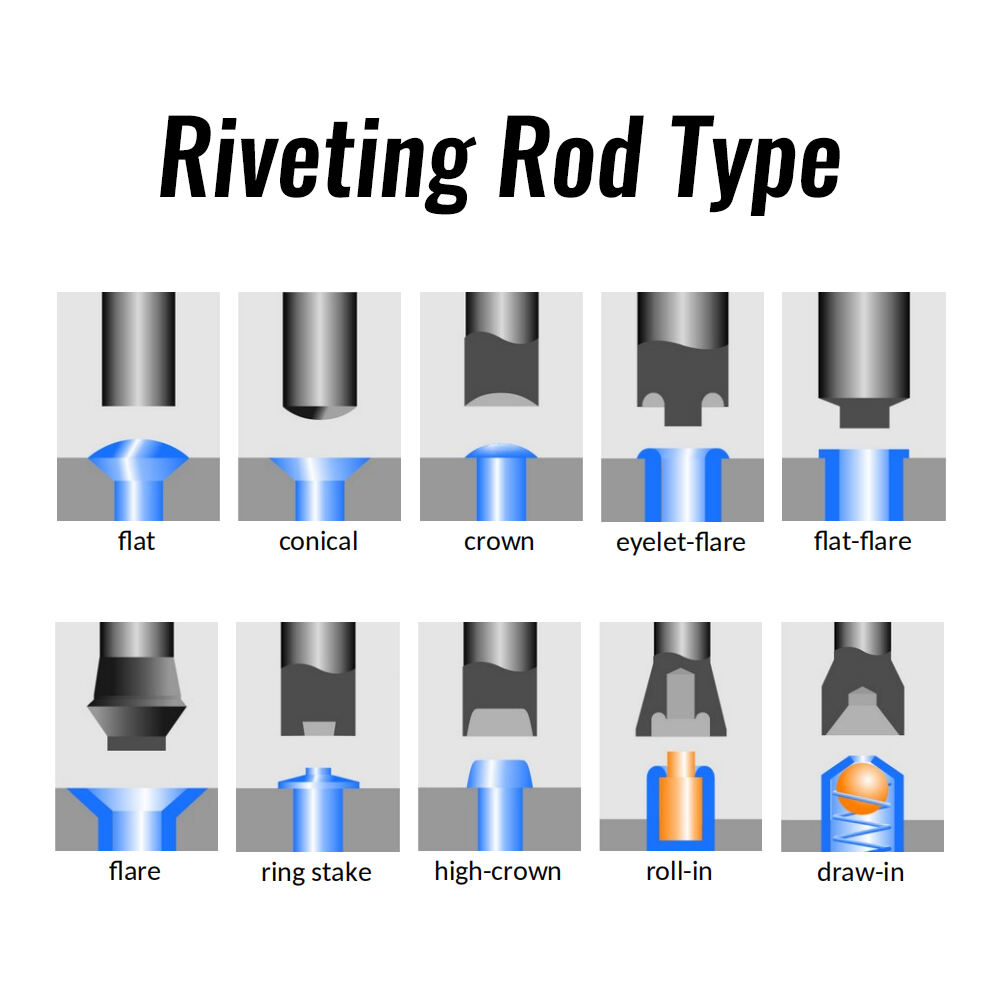

3. Rich in molding techniques

Depending on the different forms of the rivets and the specific product requirements, the heads of the screw riveting machines are made into various shapes, enabling the production of products of different shapes. Common shapes include: mountain shape, spherical shape, parallel shape, folded parallel shape, outward flange shape, pot shape, middle convex shape, etc.

4. Voltage is configured according to customer requirements.