Essential Strategies for Leveling Machine Longevity

Maintaining a leveling machine's precision and performance requires a systematic approach and dedication to regular maintenance protocols. These sophisticated pieces of equipment play a crucial role in metalworking operations, ensuring materials meet exact flatness specifications. Without proper maintenance, even the most advanced leveling machine can deteriorate, leading to costly downtime and quality issues.

Industry experts emphasize that consistent maintenance not only extends equipment lifespan but also preserves the high precision these machines are designed to deliver. By implementing a comprehensive maintenance strategy, facilities can protect their investment while ensuring optimal production quality.

Preventive Maintenance Fundamentals

Daily Inspection Protocols

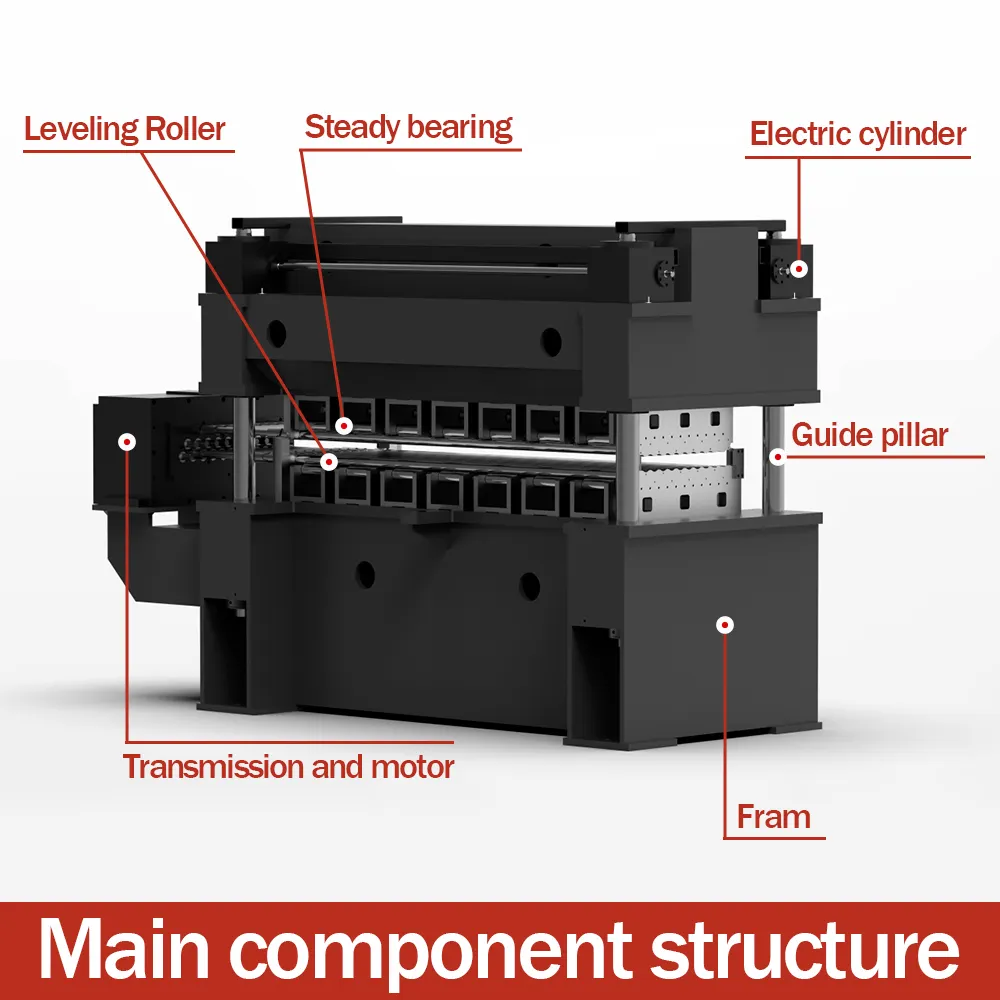

The foundation of effective leveling machine maintenance begins with daily inspections. Operators should conduct thorough visual checks of all critical components before starting production. This includes examining roller conditions, checking hydraulic fluid levels, and monitoring drive system performance. Any unusual sounds, vibrations, or operational irregularities must be documented and addressed promptly.

Developing a standardized checklist ensures no crucial inspection points are overlooked. This systematic approach helps identify potential issues before they escalate into major problems that could affect machine precision or cause unexpected breakdowns.

Lubrication Management System

Proper lubrication is paramount for maintaining leveling machine accuracy and preventing wear on critical components. A well-designed lubrication management system should specify the correct lubricant types, application points, and frequency of application. Modern leveling machines often feature automated lubrication systems, but these still require regular monitoring and maintenance.

Maintaining detailed lubrication logs helps track consumption patterns and identify potential issues early. Regular oil analysis can provide valuable insights into machine health and help optimize lubrication intervals.

Advanced Calibration Techniques

Precision Measurement Tools

Maintaining leveling machine accuracy requires regular calibration using specialized measurement tools. Digital indicators, laser alignment systems, and precision levels are essential for verifying and adjusting machine parameters. These tools must themselves be regularly certified to ensure their accuracy.

Creating a calibration schedule based on production volume and material types helps maintain consistent product quality. Documentation of all calibration procedures and results provides valuable historical data for tracking machine performance over time.

Adjustment Procedures

When calibration measurements indicate the need for adjustments, following manufacturer-specified procedures is crucial. This includes proper tensioning of leveling rolls, alignment of entry and exit guides, and verification of parallel roller positioning. Each adjustment must be performed methodically and verified before returning the machine to production.

Training maintenance personnel in proper adjustment techniques ensures consistency and prevents inadvertent damage to sensitive components. Regular skill updates and certification programs can help maintain high maintenance standards.

Component Care and Replacement

Roller Maintenance Strategy

The leveling rolls are the heart of the machine and require special attention. Regular inspection for wear patterns, surface damage, or coating deterioration is essential. Implementing a roller rotation schedule can help distribute wear more evenly and extend component life.

Maintaining detailed records of roller condition and replacement history helps optimize maintenance schedules and budget planning. When replacement is necessary, using only manufacturer-approved components ensures continued precision performance.

Drive System Upkeep

The drive system, including motors, gearboxes, and control components, requires systematic maintenance to ensure precise operation. Regular monitoring of motor current draw, temperature patterns, and vibration levels can identify developing issues before failure occurs.

Implementing predictive maintenance techniques, such as vibration analysis and thermal imaging, helps prevent unexpected drive system failures. This proactive approach minimizes downtime and maintains consistent leveling quality.

Environmental Control Measures

Temperature Management

Maintaining stable environmental conditions is crucial for leveling machine precision. Temperature fluctuations can affect material properties and machine components. Installing appropriate climate control systems and monitoring temperature variations helps maintain consistent operation.

Regular cleaning of cooling systems and verification of temperature sensor accuracy ensures optimal environmental control. This attention to environmental factors contributes significantly to long-term machine precision.

Contamination Prevention

Protecting the leveling machine from contamination requires a multi-faceted approach. This includes maintaining clean workspace conditions, using appropriate filtration systems, and implementing strict cleaning protocols. Regular inspection and cleaning of filters, wipers, and protective covers prevents debris accumulation that could affect machine performance.

Training operators in proper housekeeping procedures and providing necessary cleaning tools helps maintain a contamination-free environment. Regular audits of cleanliness standards ensure consistent implementation of preventive measures.

Frequently Asked Questions

How often should leveling machine calibration be performed?

Calibration frequency depends on usage patterns and material types processed. Generally, full calibration should be performed monthly for heavy-use operations, with daily verification of critical parameters. High-precision applications may require more frequent calibration checks.

What are the signs that leveling rolls need replacement?

Key indicators include uneven wear patterns, surface scoring or pitting, difficulty maintaining proper material flatness, and increased power consumption during operation. Regular dimensional checks and surface inspection can help determine optimal replacement timing.

How can operators maximize leveling machine precision between maintenance intervals?

Operators can maintain precision by following proper warm-up procedures, monitoring operating parameters closely, keeping detailed production logs, and responding promptly to any unusual machine behavior. Regular cleaning and proper material handling also contribute significantly to maintained precision.